Week 15 Wildcard

Objective

Design and produce something with a digital process

(incorporating computer-aided design and manufacturing) not covered

in another assignment, documenting the requirements that your

assignment meets, and including everything necessary to reproduce

it. Possibilities include (but are not limited to):Zund Digital Cutter

The machine I chose to use this week is Zund Digital Cutter

A Zünd digital cutter is an advanced, automated cutting machine designed to handle a wide variety of materials with high precision and efficiency. These cutters are used in numerous industries for applications ranging from prototyping and short-run production to large-scale manufacturing. The digital cutter's versatility comes from its modular design and the ability to equip it with different tools to perform various cutting, creasing, and routing operations.

Applications

1. Graphics and Signage

- Vinyl Cutting : Used for cutting vinyl for signs, banners, and decals.

- Printed Graphics : Cutting printed graphics to precise shapes and sizes.

2. Packaging

- Prototyping : Creating prototypes of packaging designs from corrugated cardboard, paperboard, and other materials.

- Short-Run Production : Efficiently producing small batches of packaging materials.

3. Textile and Apparel

- Pattern Cutting : Cutting fabric patterns for clothing and accessories.

- Soft Signage : Cutting textiles for soft signage applications.

4. Composite Materials

- Aerospace and Automotive : Cutting composite materials for lightweight and high-strength components.

- Industrial Applications : Cutting gaskets, seals, and insulation materials.

5. Leather Goods

- Fashion and Accessories : Cutting leather for shoes, bags, and other accessories.

- Upholstery : Cutting leather and fabrics for furniture upholstery.

6. Promotional Products

- Custom Shapes : Cutting promotional items like stickers, magnets, and custom-shaped cards.

7. Point of Sale Displays

- Custom Displays : Creating intricate and custom shapes for point of sale displays from various materials like foamboard, acrylic, and wood.

8. Prototyping and Model Making

- Architectural Models : Cutting materials for architectural and industrial models.

- Product Prototypes : Creating precise prototypes for product development.

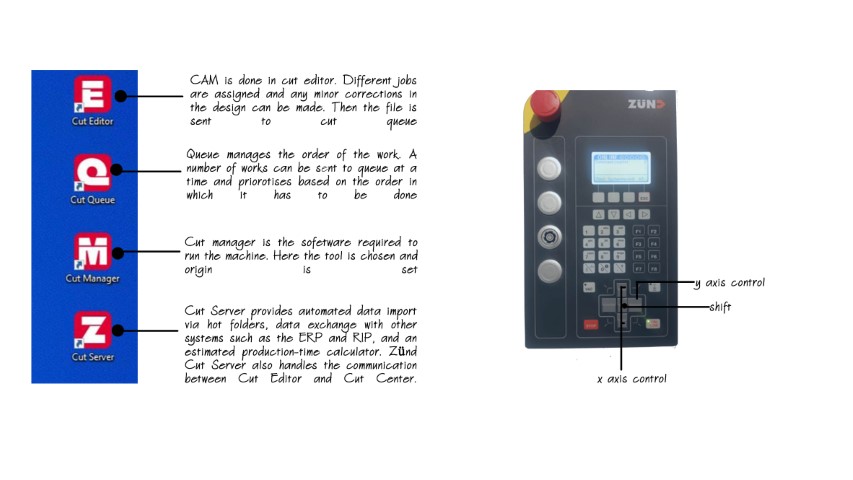

Apps used to operate Zund / Zund console

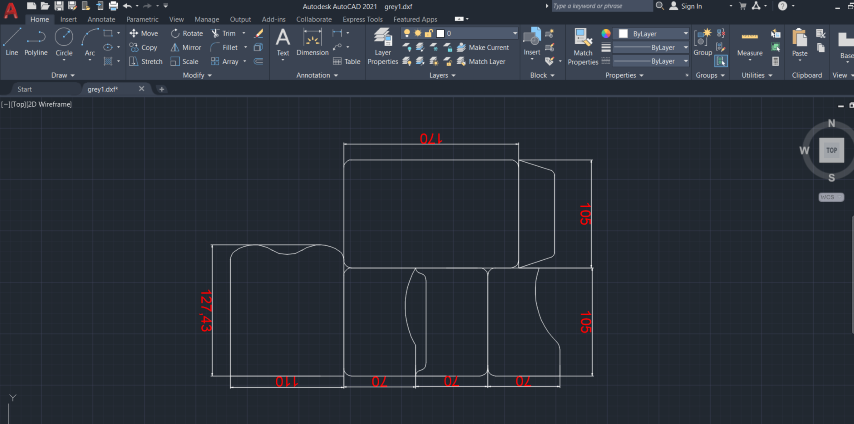

Designing In AutoCad

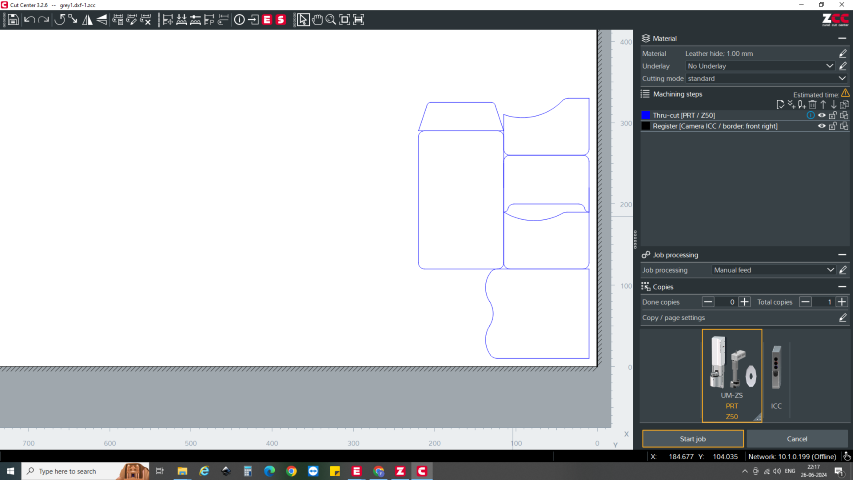

I was planning to make a wallet using leather. So that I can cut the patterns using Zund and stitch them together. I made my design in Autocad and then saved it as dxf file

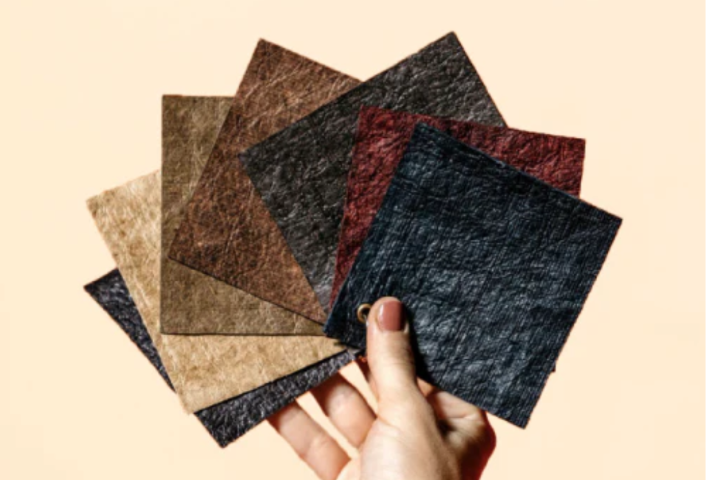

Material used: Malai Leather

Malai is a plant-based leather grown on coconut waste. The material has a feel comparable with paper or leather and repels water. Since it does not contain chemical additives, the material could be eaten. Since the coconut water would otherwise be discarded and potentially harm the soil, repurposing creates a positive impact. The leather can be formed using innovative molding, allowing it to make three-dimensional shapes.

You can find more details about the material here

Cutting in Zund

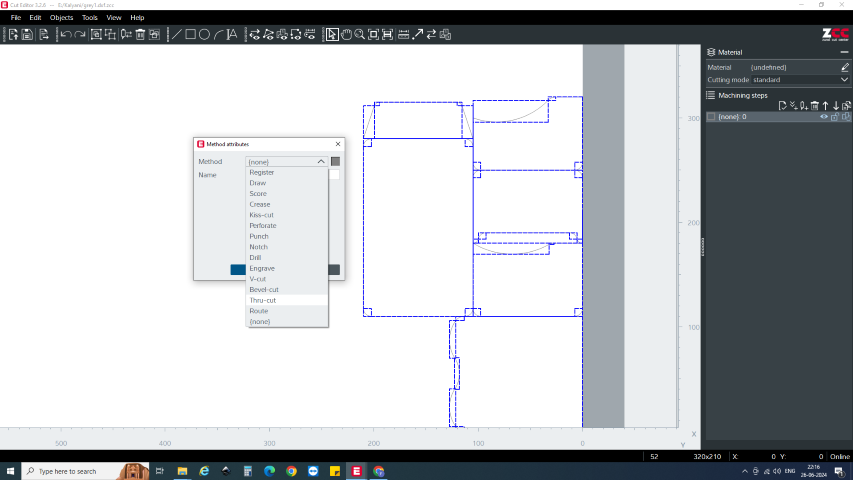

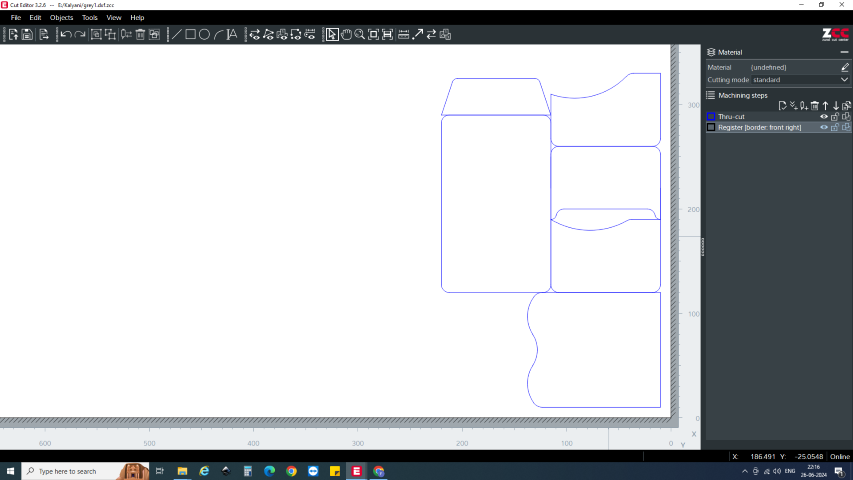

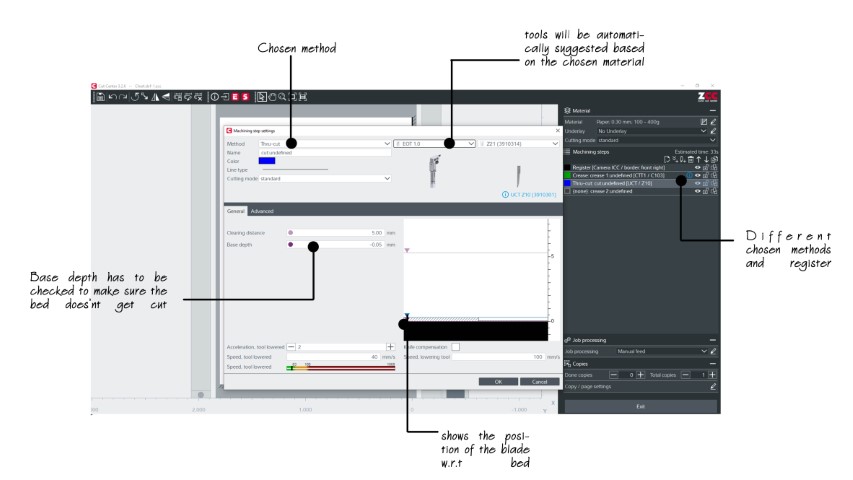

- Open the file in the cut editor and assign operations after selecting the required lines

- Register the operation as front right

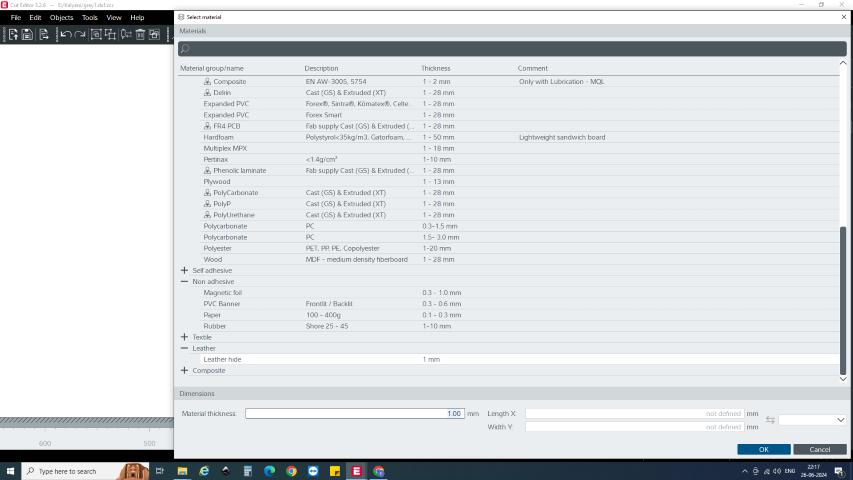

- Select the required material and add thickness

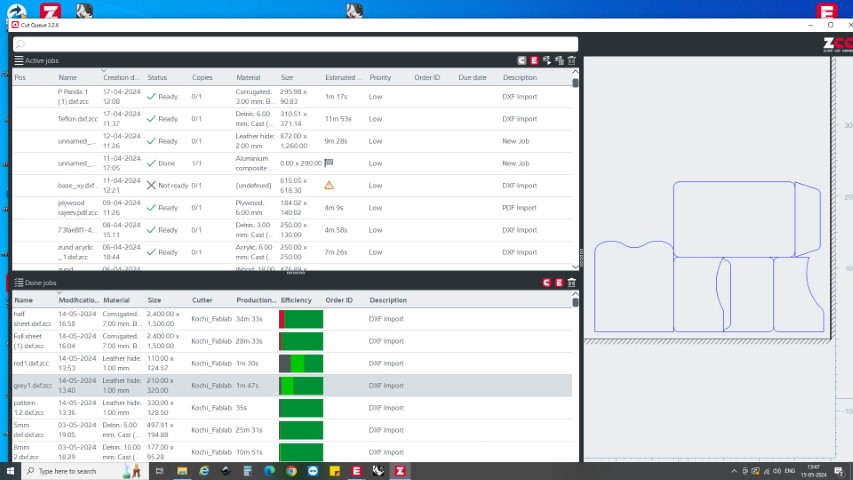

- Open cut queue and select the required job from the queue

- you’ll get a dialog box like this when you double-click on the job

- Once you have added all the settings start the job

Assembling the pieces

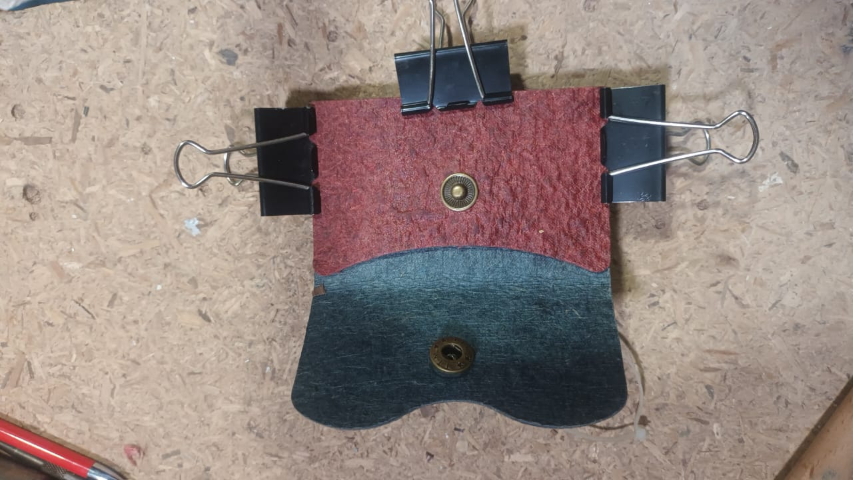

- I tried cutting different colors

To combine the pieces together we can either use glue or stitch them. I chose to stictch. So we’ll have to create holes to do the stitch

- Holding the piece in place using clips in order to make holes.

Creating holes was one of the difficulties I faced. I did it manually which is something I plan on doing in zund itself the next time.

Stitching

Stitching was the most time-consuming part but it was equally satisfying

Tools used

Final result/hero shot

This is the final outcome. I gifted it to a friend to store cards in it and she liked it very much.